For the first time in surgical history, a 3D-printed ceramic subperiosteal jaw implant was placed in a patient as part of the INKplant project. Lithoz, long-standing Associated Member of the Cluster, once again demonstrates the enormous innovation potential of ceramic 3D printing with this research contribution. The high precision of Lithoz LCM technology and the design freedom of 3D printing made this ceramic jaw implant “under the periosteum” possible.

The ambitious INKPLANT project unites 19 partners from seven countries, including Cluster members LBI Trauma and Lithoz, coordinated by Profactor GmbH and funded by the European Union. The project aims to create 3D-printed patient-specific implants to treat various pathologies affecting the elderly. Now, in a major breakthrough for medical applications, a 3D-printed ceramic subperiosteal jaw implant was successfully placed in a patient for the first time ever.

Lithoz, one of the partners in the project, has been researching the optimal fusion of various biomaterials with the advantages of 3D printing since 2021. The implant was developed with and built by Austrian ceramic 3D printing specialist Lithoz to address the issue of atrophic jaws, a common problem in older patients. After the loss of teeth, the jawbone disappears as well, resulting in atrophic jaws and rendering the use of dentures impossible. With severe atrophy, conventional dental implants require additional lengthy operations to graft new bone to anchor the implants. Such operations are difficult for elderly patients who cannot undergo bone grafting due to health

issues.

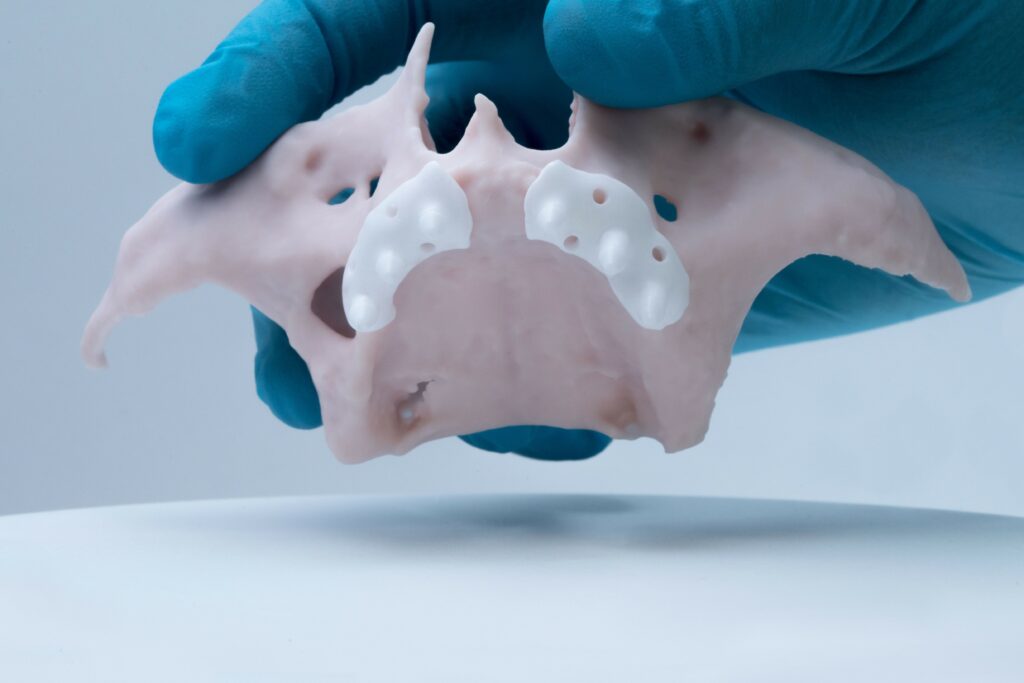

A patient at Kepler University Hospital, who had lost multiple dental implants and bone grafts in the past due to his compromised health, was unable to receive further conventional surgical strategies as a result of significant scarring and thus received the new implant as a compassionate use case. Made of biocompatible high-strength zirconia using Lithoz LCM technology, the implant did not require any bone augmentation and required only one procedure, reducing healing time by an estimated 75% and avoiding excess trauma for the patient. Thanks to this synergetic innovation in design and material, all the necessary surgical procedures were completed in a single operation. The surgery, led by DDr. Christoph Staudigl, was a successful world first use of a ceramic subperiosteal jaw implant in a compassionate use case on a patient. Despite some expected wound healing issues after surgery, the superior soft tissue compatibility of zirconia compared to titanium played its role spectacularly. The implant showed clinical stability after 60 days, representing a decisive breakthrough for the treatment of severely atrophic jaws.

The design of the customized implant was pioneered by the Centre for Medical Physics and Biomedical Engineering at the Medical University of Vienna in collaboration with DDr. Staudigl. During the design process, BTI Biotechnology Institute (Vitoria-Gasteiz, Spain) and BioMed Centre Innovation GmbH (Bayreuth, Germany) also contributed significantly with their expertise. The implant will be patented and adopted as a medical device by BioMed Centre spin-off Agensmed GmbH and will be manufactured using Lithoz 3D printers. A clinical trial is being prepared to systematically validate its efficacy.